- Thakkarbapa Nagar, Ahmedabad, Gujarat

- GST NO. : 24AKXPP2583N1Z7

- View Mobile Number

| Business Type | Manufacturer, Exporter, Supplier |

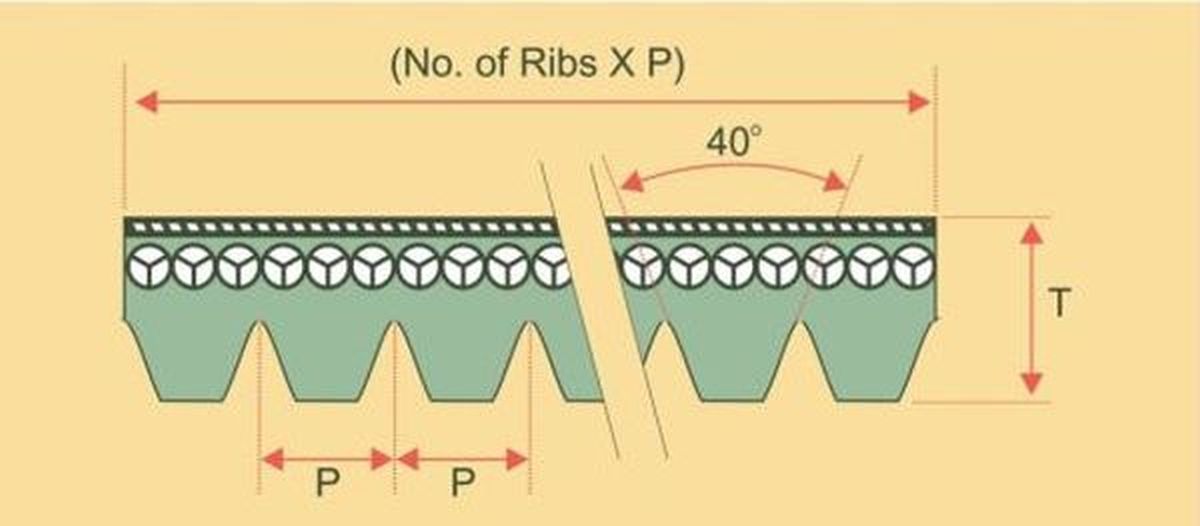

Figure of Poly V Pulley

Technical Specifications

| Belt Section | Pitch in mm (P) | Thickness in mm (T) | Maximum Nos. of Ribs / Sleeve | Function |

| H | 1.6 | 2.9 | 24 | Fractional Horse Power for very light duty applications |

| J | 2.34 | 3.8 | 96 | High linear speed up to 60 m/s in “J” section, Low cost for light duty applications |

| K | 3.56 | 4.5 | 24 | Designed specifically for the automotive industry, it is also suitable for Machine Tools drives etc |

| L | 4.7 | 7 | 50 | Medium duty drive covering a wide range of applications |

| M | 9.4 | 13.5 | 40 | High performance makes it unrivalled for heavy duty applications |

Groove Dimensions as per ISO 9982 /DIN 7867

Advantages / Features of Poly V Pulley (Poly V Sheave Pulleys / V Belt Groove Pulleys)

- Compact Drive - Poly V Belt Pulley can be used with smaller pulley diameters to give a lighter and compact drive

- Single Belt - Always single belt is used which avoids any problems arising out of length differences and single belt can drive several accessories

- Reduced Diameter - Diameter upto 9mm with the “H” profile, compare to 50mm with V belts

- Reduced Belt Width & Length - Belt width & length can be reduced for a given geometry and the same power transfer

- Reduce Consumption - It reduces consumption due to higher output

- Higher Power - In compare to conventional V-belt pulleys, it consumes 40% high electric power per unit

- Zero Slippage - It eliminates slippage due to maximum wedge contact on the pulleys

- Higher Bearing Life - It gives higher life to bearings due to lesser static tension

- Silent Drive - Low Noise and Vibration free without generating heat in every application

- Higher Speed - Very High Power Transmission Ratio 1.60 v/s 1.20 in V-belt pulleys, it can be used at higher speed more than 40m/sec.

- Facilitate Machining - It can be used on smooth pulleys i.e. receivers pulleys, There is no need for matching belts and it extends life span

Application of Poly V Pulleys ( Poly V Sheave Pulleys / V Belt Groove Pulleys) :

- Engineering :

- Machine Tools : It is used in CNC Milling & Turning Machines to operate high speed ratio at small diameter, to enhance surface finishing, to avoid vibration

- Heavy Industries : Hammer Mill and Extrusion Press where power consumption is high upto 600 kw by using single belt which requires greater machine efficiency.

- Drilling Equipment, Industrial Saw Mill to use high torque transmission and avoid vibrations

- Refrigeration Systems :

- Industrial & Vehicles Air conditions : Consistency in Structure, Energy Efficient, Easy to drive compressor as an option

- Freeze container : It increase operating life, Its compact drive can reduce diameters and width of pulleys

- Centrifugal Fan : It can be used due to high abrasion resistant, to increase the possible ratio 1.6 and flat driven pulley at ratio > 4

- Air compressor : It increase output, consumes low electricity, low noise and maintenance

- Food Processing Machinery : To avoid functional slippages under jam conditions used in Food processing mixer & pump, Flour Mill, Bread Making Machines, Ice-cream and Coffee Machine etc

- Roller Conveyor : It can perform high to transfer light, medium and heavy load (from 400 kgs to 2mts)

- Constructions : Concrete or Cement mixers, Thermal Engines, Cranes, Excavator, Vehicle engines, Saw Mills (cutting stone or metal sheet), Steam Roller etc.

- Agriculture & Gardening : Modern equipments in Cultivation, Harvesting, Collection of crops like Tractors, Food Grinding Machineries, Lawn Mover machines, Scrub cutter, Stone Crusher, Vegetable Crushing machines, Spraying equipments etc

- Power Generation : Wind Turbines, Generator, Mini Hydro Power plant

Looking for "Poly V Pulley" ?

Piece